Spending a few days of vacation in July in Worland may not be the coolest place to be. But it can still be productive. Days like this, we ranch in the morning and find a shade tree or mechanic in the afternoon. Today it got to 102. Not a good day to be building fence. So, to the shop we go.

Thursday, July 11, 2024

Brakes and Shocks

I had brakes put on White Horse a couple years ago. My biggest beef with the job is that they put on ceramic pads. Maybe in some situations they work well, but not on a ranch truck. They seemed to just slide and not really grab and stop. So I tried some regular Napa HD pads on the front about a year ago, and problem solved. I've been wanting to replace the rear, but haven't found the time until now.

The deal with front brakes is that they do most of the work. So I knew they were being over worked. If I were to just put new pads on the rear, they would be way out of sync with each other, wearwise. Thankfully, the front and rear pads are the same. So I set out to put the front pads on the rear and put the new pads on the front. It's complicated.

So we stuck all four in the air. When working with weight like this, take no chances. Make sure your jack stands are rated for the job.

Then pull the wheels off and see what we got. Air is out. Cordless is in.

A lot of brake dust on the front.

And little to none on the rear.

The rotors look real good. When I had the brakes done a while back, they turned the discs and trued them up.

Before you pull the caliper, do your best to retract the pistons. This will pay off on the reinstall, especially if you're putting on new pads.

Then bust the two bolts loose.

Some times you have to use a cheater pipe, if they're too tight and you need some extra leverage.

Here's a look at the front vs. the back. Not a lot of wear difference.

But the ceramic pads have quite a glaze to them and plenty of heat cracks. They're gone.

Pretty much install the new pads in the same way the old ones came out.

And tighten them up. The calipers need a little wiggle room so they are never going to be ridged. The bolts need to be good and tight, 90 foot pounds or so. But their job is to keep the caliper in position so it keeps itself centered as the pads go in and out, and wear down and such.

Then to the shocks. I've never changed the shocks on this truck. It's a ranch truck, it's supposed to ride rough. But getting the bounce effect out of it would be nice. So while the wheels were off, we tackled the shocks as well. Side note, if shocks show signs of oil leakage, they're shot.

Napa is my go to parts store if I can't afford OEM.

Look pretty. HD of course.

Save yourself time. Use power tools when you can.

Swivel headed ratchets can't be beat.

I found that if you put the bottom bolt in first you don't have to fight lining it up later.

Tighten all the bolts up, good and sound.

Looks better.

The back were even easier.

Once you cut this strap, be ready to stab your bolt in. If you miss it on the first try, like I did, it can be recompressed by hand.

Once the brakes and shocks were done, it's time for rubber. This is a good opportunity to rotate the tires. I generally go back to front, and front diagonally to the back. These BFG's are holding up good. They might even make it through the winter.

If you use impact tools to drive the lug nuts on, don't hammer them on. Ideally, tires should be torqued on. Especially tires with disc brakes. This helps prevent rotor warpage. I'll usually zip them on flush with an impact, then try to put the same torque on by hand. Truck lugs like these can handle about 110 foot pounds.

Good time to adjust the tire presser as well. Believe it or not, there is such thing as winter air and summer air. Air expands in the heat causing more psi., and contracts in the cold, causing lower pressure.

Back in business.

I do enjoy turning a wrench. Trucks will run a long time if you keep them maintained. Shocks can be overlooked because they have to do with the ride, but they also help in highway handling. The brakes... not something to compromise. If you drive right, you can make brake pads last a long time. But before thinking about longevity, you have to think effectiveness. Ceramic pads might work well in NASCAR, but not pulling a horse trailer. We're back in action now and ready to run. But more importantly, ready to stop!

Wednesday, July 10, 2024

Spark Plugs

Basic engine tuneup usually consists of new plugs and wires. Used to be, if you could get 100k miles out of a set spark plugs you did pretty good. I changed White Horse's plugs at 125k but didn't feel the need to change them again until now. With 325k miles on her, it seems like a good time for new spark plugs and new plug wires as well.

This 6.0 is still strong. No hiccups in the last 12 years. About every 5k miles she burns 1/2 quart of oil.

Here's a little mechanic's trick. When working over the fender, quarter turn your belt buckle. You won't scratch your truck paint and your britches will still stay up.

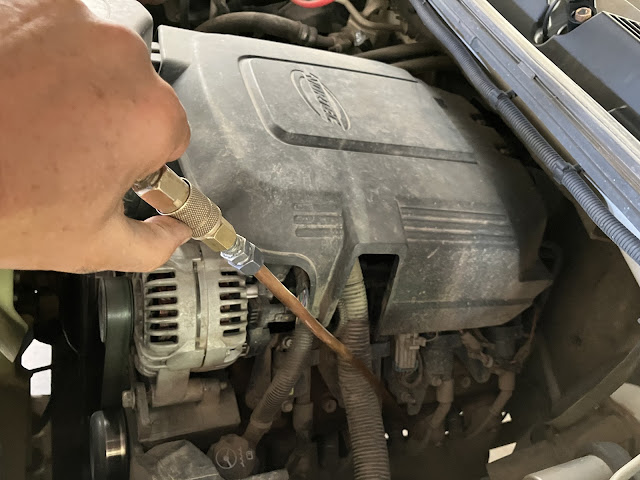

First thing I do before I work on spark plugs is blow all the dirt away from the plug port on the cylinder head. This is a good idea because when you pull the plug out or put it back in you could drag dirt into the combustion chamber.

Pulling the wire off the plug is one of the hardest parts. Try to avoid pulling on the wire itself. Grab and wiggle the cap over the plug and you should be good.

They make actual spark plug sockets that have a rubber grommet inside that centers and protects the plug. I like to shoot a little WD-40 on the rubber so that it slides on and off easier.

Breaking them loose can be tough. Just get a good grip and watch your knuckles.

Here you can see the old and the new. Definitely needed to be changed. I'm actually surprised these old ones still sparked with a gap like that. Most plugs come pre-gapped with the right tolerance. Though, it's not a bad idea to double check them. I didn't on these.

Chevy has been running their small block V8 since the 1950's. I'm sure this 6.0 has some tweaks since then, but it's basically the same blueprint. Four sets of plugs on the drivers and four on the passengers. There is less clutter on the drivers side, but you have the steering shaft to contend with. On the passengers there's plenty of hoses and more. A light is usually of help.

Tightening spark plugs is crucial. It is important to use one hand as a fulcrum on the ratchet head and one to do the torquing. Once the plug bottoms out, I like to give them a good 50 foot pounds of twist.

I also like to keep all the old plugs in order, so if you see one with some oddities you know which cylinder it came out of.

If you're going to New York, don't stop in Chicago. We've come this far, might as well replace the wires as well.

These newer vehicles don't have a distributer cap, but individual coils for every cylinder. Therefore, the plug wires are all the same length. Make sure every one has a good click sound on both ends as you install them.

Bring it.

Changing spark plugs and wires is a pretty easy tuneup. Usually you're not out too much cash. And as long as you don't foul anything up, it can only help things. That being said, there's no use doing it too soon. However, 225k miles the same spark plugs is probably long enough. With new territory to cover, we better be ready to run. Let's ride.

Monday, July 8, 2024

Pivot Break Down

Seems like every time I come home, the pivot sprinkler breaks down. This time it shut off from being out of alignment. Dad had a hunch that it was a driveline problem. Sure enough.

With the barley ripening, a guy wants to keep the water on it.

So we ventured out, tools in hand.

The barley really looks good this year around the basin.

Coors malt barley is a signature two row barley called Moravian.

These knuckles act like a u-joint and are no stranger to going out.

With all the water running on them, it's usually easier to just brake the bolts rather than mess with a socket and ratchet.

The other end was pretty worn too. So changed it as well.

But the square shaft was no longer square.

So we put a bolt down the middle to really receive the torque.

Then back out we went.

Bolted right up.

Back in business.

Beings the pivot was out of alignment, we just reversed it until it came back in line. Then kicked it forward to finish the job.

Giddy up.

The barley is not far from ripe. On the edges of the field it always matures sooner because it doesn't get as much water. When malt barley starts to bend over, it's ready to harvest.

July is a pretty hard irrigation month around the Big Horn Basin. One last time on the barley, the alfalfa will take all you can give it, corn enjoys a drink, and sugar beets like wet soil and hot air to build their beet. Pivot sprinklers have revolutionized farming around here. But it comes with the price of maintenance. Like Grandpa always said, anything mechanical is going to break down. Guess it wouldn't be much fun if it didn't. That’s farming.

Sunday, July 7, 2024

Lungrens and Lairds

In 1917 the Holly Sugar Company started a sugar beet factory in the Big Horn Basin. Upon this news, the Lungren family moved to Worland in 1922. The first farmer to hire them on was L.E. Laird. This was a big step for the Lungrens, who after working for the Lairds never left the Worland area.

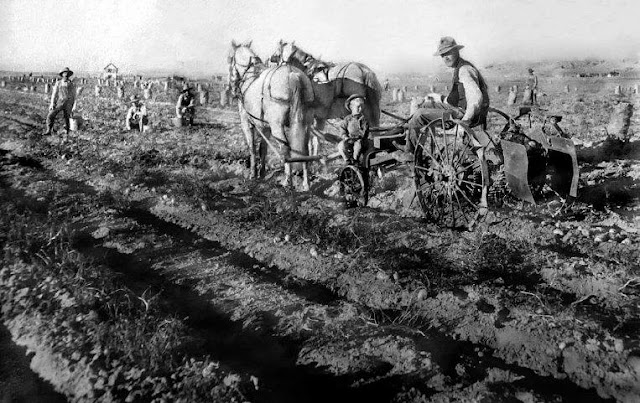

The Big Horn Basin originally grew hay, barley, corn, and potatoes. Sugar beets had not entered the region until the early 1900's. Here L.E. Laird and his son Russel sit upon a one row potato digger.

L.E. Laird's grandson Loren still remains on the Laird farm, which sits directly east of Worland. On Sunday afternoon he had Dad and I out to talk a little history.

L.E. Laird was one of the early settlers in the Worland area.

Back then, if you signed on to help build the canals, which were engineered to carry water from the Big Horn River to potential farm ground, you could buy land from the canal companies. Here, L.E. Laird swings a sledge hammer during the building of the Hanover Canal. Through this exchange, he was able to purchase the land east of town and break it out for the first time.

By 1922, the Laird farm was growing sugar beets, and the Lungren family worked the fields for them. They also stayed on during the winter. By this time, Adam Lungren, my great grandfather, was leading the charge of the family, which then consisted of his dad and some siblings as well as his own wife and five children. My grandfather, Lloyd, was born in 1925 while the family lived here on the Laird farm.

The Lairds were good to the Lungrens. So much so that Loren's Aunt Bernice became the namesake for one of Grandpa Adam's daughters.

The Lungrens worked for the Lairds until 1926. After that they began to break into farming on their own. Great-grandpa Adam is in the back second to the right. His daughter Bernice is in the back second to the left. My Grandpa Lloyd is right in the center.

L.E. Laird's influence in helping the Lungrens get settled didn't end on his farm. Being on the board of the Holly Sugar Company he was tasked with selling some farms that the factory owned. In 1942, L.E. Laird helped Adam Lungren purchase this 272 acre farm two miles south of Worland. Here, Adam and two of his boys farmed and fed livestock. Dad grew up on this place and I spent my summers out here as well. To this day, the farm remains in the Lungren family where they continue to raise sugar beets.

Special thanks to Loren and his daughter Mary for helping us experience some of our rich family history. I find that the deeper a guy taps into his family roots the more he can appreciate the life he has been given. Not that we don't have a part to play for the generations to come, but we build on the shoulders of giants. Adam Lungren was a work horse. And as a God fearing man, the Lord provided for him. One of those great gifts in his life, and consequently my life, was his connection to the L.E. Laird family. So from the Lungren family to the Lairds, thank you.

Saturday, July 6, 2024

Home on the Range

As always, God provides. I left the horses back in Campbell County until I got a lay of the land over here in Buffalo. Well, in no time I had people offer me pasture.

Suzie Kirvinskee reached out and said that her and her husband Galen have a few acres that is more than their one old horse will get through. So I came out and took a looksee.

Beautiful place, southwest of town. Right at the foothills of the Big Horn Mountains. Probably about 7 acres with a barn and two stalls.

Not enough for all three horses, but perfect for Red. I’d like to have him near by so I can keep putting miles on him. Looks like Suede and him should get along just fine.

After the two were introduced, we walked the fence and explored the pasture.

Found a couple down wires from the winter. If you look close to the ground you can often find the fallen staple around the base of the fence post. Then in a pinch, you can use a rock to pound in back in.

Should work.

Good company.

I think Red and Suzie are going to get along just fine. Once I get settled I hope to spend some time riding these hills. Just across the fence is a lot of State ground. Sounds like fun to me. Thanks Suzie and Galen. Let’s ranch!

Thursday, July 4, 2024

Subscribe to:

Posts (Atom)

-

Husband and wife are like two eyes of one body that contemplate the depths of Heaven. https://youtu.be/oL60RZ1-3yI

-

Carmelite Monks? I thought there were only friars and nuns. Not in Wyoming. In 2003, through the inspiration of the Holy Spirit and the dire...

-

The beauty about being Catholic is that everyone is family. The fun part of that is meeting new members. Carson Kitaf is a seminarian for th...