Spending a few days of vacation in July in Worland may not be the coolest place to be. But it can still be productive. Days like this, we ranch in the morning and find a shade tree or mechanic in the afternoon. Today it got to 102. Not a good day to be building fence. So, to the shop we go.

I had brakes put on White Horse a couple years ago. My biggest beef with the job is that they put on ceramic pads. Maybe in some situations they work well, but not on a ranch truck. They seemed to just slide and not really grab and stop. So I tried some regular Napa HD pads on the front about a year ago, and problem solved. I've been wanting to replace the rear, but haven't found the time until now.

The deal with front brakes is that they do most of the work. So I knew they were being over worked. If I were to just put new pads on the rear, they would be way out of sync with each other, wearwise. Thankfully, the front and rear pads are the same. So I set out to put the front pads on the rear and put the new pads on the front. It's complicated.

So we stuck all four in the air. When working with weight like this, take no chances. Make sure your jack stands are rated for the job.

Then pull the wheels off and see what we got. Air is out. Cordless is in.

A lot of brake dust on the front.

And little to none on the rear.

The rotors look real good. When I had the brakes done a while back, they turned the discs and trued them up.

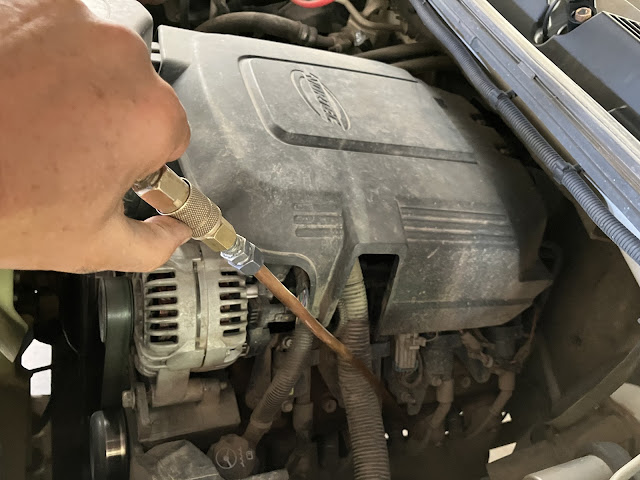

Before you pull the caliper, do your best to retract the pistons. This will pay off on the reinstall, especially if you're putting on new pads.

Then bust the two bolts loose.

Some times you have to use a cheater pipe, if they're too tight and you need some extra leverage.

Here's a look at the front vs. the back. Not a lot of wear difference.

But the ceramic pads have quite a glaze to them and plenty of heat cracks. They're gone.

Pretty much install the new pads in the same way the old ones came out.

And tighten them up. The calipers need a little wiggle room so they are never going to be ridged. The bolts need to be good and tight, 90 foot pounds or so. But their job is to keep the caliper in position so it keeps itself centered as the pads go in and out, and wear down and such.

Then to the shocks. I've never changed the shocks on this truck. It's a ranch truck, it's supposed to ride rough. But getting the bounce effect out of it would be nice. So while the wheels were off, we tackled the shocks as well. Side note, if shocks show signs of oil leakage, they're shot.

Napa is my go to parts store if I can't afford OEM.

Look pretty. HD of course.

Save yourself time. Use power tools when you can.

Swivel headed ratchets can't be beat.

I found that if you put the bottom bolt in first you don't have to fight lining it up later.

Tighten all the bolts up, good and sound.

Looks better.

The back were even easier.

Once you cut this strap, be ready to stab your bolt in. If you miss it on the first try, like I did, it can be recompressed by hand.

Once the brakes and shocks were done, it's time for rubber. This is a good opportunity to rotate the tires. I generally go back to front, and front diagonally to the back. These BFG's are holding up good. They might even make it through the winter.

If you use impact tools to drive the lug nuts on, don't hammer them on. Ideally, tires should be torqued on. Especially tires with disc brakes. This helps prevent rotor warpage. I'll usually zip them on flush with an impact, then try to put the same torque on by hand. Truck lugs like these can handle about 110 foot pounds.

Good time to adjust the tire presser as well. Believe it or not, there is such thing as winter air and summer air. Air expands in the heat causing more psi., and contracts in the cold, causing lower pressure.

Back in business.

I do enjoy turning a wrench. Trucks will run a long time if you keep them maintained. Shocks can be overlooked because they have to do with the ride, but they also help in highway handling. The brakes... not something to compromise. If you drive right, you can make brake pads last a long time. But before thinking about longevity, you have to think effectiveness. Ceramic pads might work well in NASCAR, but not pulling a horse trailer. We're back in action now and ready to run. But more importantly, ready to stop!