God is our advocate not our accuser.

Monday, March 27, 2023

Sunday, March 26, 2023

Hauling Hay

With this extra long winter, the horses are almost out of hay. Remembering that about 3:30 this morning, I decided we better head to Hulett early to get some. Thankfully, Maverik had just finished making their first batch of Bonfire Burritos when White Horse and I hit the trail at 4:30.

Ole Reliable

Beings I wasn't able to call ahead of time, I was a bit worried that Jim might meet me with a shotgun. Fortunately, he told me that he always fires a warning shot.

Might as well make the trip worth while.

After celebrating Mass in Hulett and Moorcroft, we arrived home safe and sound. Only had to stop three times to adjust the load.

Happy campers.

I honestly love ranching. Being responsible for critters and having to fight to keep them fed is invigorating. Such wholesome activity fuels my priesthood. Homilies come easy because I'm operating out of the human nature God blessed me with. On to the next one.

Friday, March 24, 2023

Saddle Repair

I really like my Billy Cook saddle, but I've always felt it sat too far forward on my horses. It doesn't seem like a big deal, but it would sure be nice if it sat further back. After visiting with folks, it turns out that there are different rigging positions that saddles come with. So I thought, if there options, why not adjust my saddle's cinching up point.

The main three rigging positions on a western saddle are full, 7/8, and 3/4. Full is directly under the swells, 7/8 is probably where this saddle is, and 3/4 is further back. I wanted this saddle to be full, so we set out to move where the latigo attaches to the saddle.

I picked up a solid brass D-ring at Thar's tack store in Gillette. It took many evenings of pondering to come up with a game plan. But in the end, there was only one way to find out if it would work.

So we cut the rivets attaching the regular rigging points on both sides of the saddle, in order to braze the new D-ring on them.

Brazing is a way of welding almost any metal. It's not the strongest weld, but is particularly good for brass. A gas welding tip is essential. Bring the oxygen up until you form a nice dark blue cone.

I find that you don't necessarily want to melt the metal like you do in normal welding. The brazing rod melts at a lower temp than most metal so the idea is to get the metal up to the heat of where to rod wants to melt and then you can fuse the two together. Generally speaking you are looking for functionality with brazing and not class.

Should work. I put the weld on the inside in order to avoid the criticism of professional of onlookers.

Then it was time to reattach. Rivets are the best for leather. These guys you just push them through, hammer the washer down, cut off the excess, and peen the left over rivet. We also added another rivet on the new D-ring for extra support.

Money.

I'm hopeful. Saddles are designed a certain way, but I don't think this will negatively affect the way it sits on a horse. Actually, I hope that the tree fits the horse better. Billy Cook's are good saddles but I think the tree is a bit narrow. It puts white wear spots on both of my horses. It doesn't sore them, but it seems to be undue pressure. All that being said, now we have options. Spring is coming and you want to be ready when it arrives. Time to ranch.

Tuesday, March 21, 2023

Monday, March 20, 2023

Sunday, March 19, 2023

Thursday, March 16, 2023

Wednesday, March 15, 2023

Tuesday, March 14, 2023

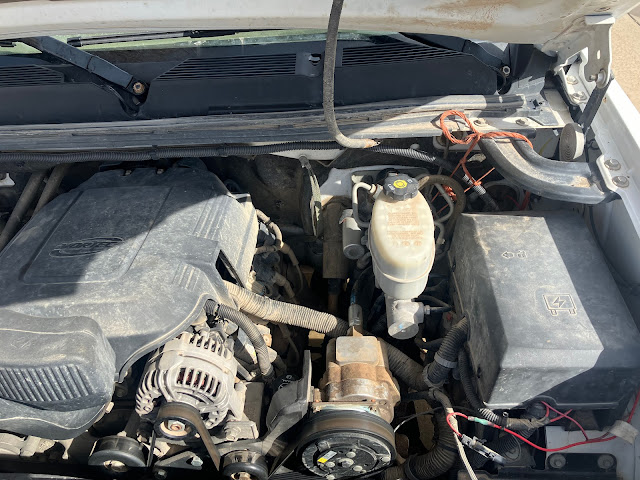

Power Steering

My power steering pump had been leaking and making noise for a while. We'll Sunday evening, she gave up the ghost. So I called Ernie to borrow a truck and Dave to borrow his shop, picked up a pump at the dealer, and went to work.

One thing I love about White Horse is she's simple. Small block Chevy just like my truck in high school, basically. One thing we have on this girl, though, is a hydraulic pump for the flatbed, which sits right over the power steering pump.

No YouTube video here. We just went for it. Once the hydraulic pump was out of the way and the alternator was set aside, we could start to see the pump more clearly.

In the end, it was easier just to remove the whole bracket with the pump still attached.

The new pump didn't come with a pulley, so I ran down to a shop up the road and they switched them for me.

Bam! Back in business.

When you're pushing 300k miles, breakdowns are bound to happen. I plan on this being the last pickup I buy so I replace what I can with GM parts. Special thanks to Ernie and Dave for their generosity. A desperado like me is quite dependent on the assistance of others. May God greatly reward you. On to the next one!

Monday, March 13, 2023

Subscribe to:

Posts (Atom)

-

Carmelite Monks? I thought there were only friars and nuns. Not in Wyoming. In 2003, through the inspiration of the Holy Spirit and the dire...

-

The beauty about being Catholic is that everyone is family. The fun part of that is meeting new members. Carson Kitaf is a seminarian for th...

-

On the feast of St. Joseph we finished our third annual picnic table for the John Paul II school fundraiser. Hopefully the recipients will e...